IMPORTANT INSTRUCTIONS - OPERATING MANUAL IMPORTANT INSTRUCTIONS - OPERATING MANUAL

CEILING MOUNT INSTALLATION

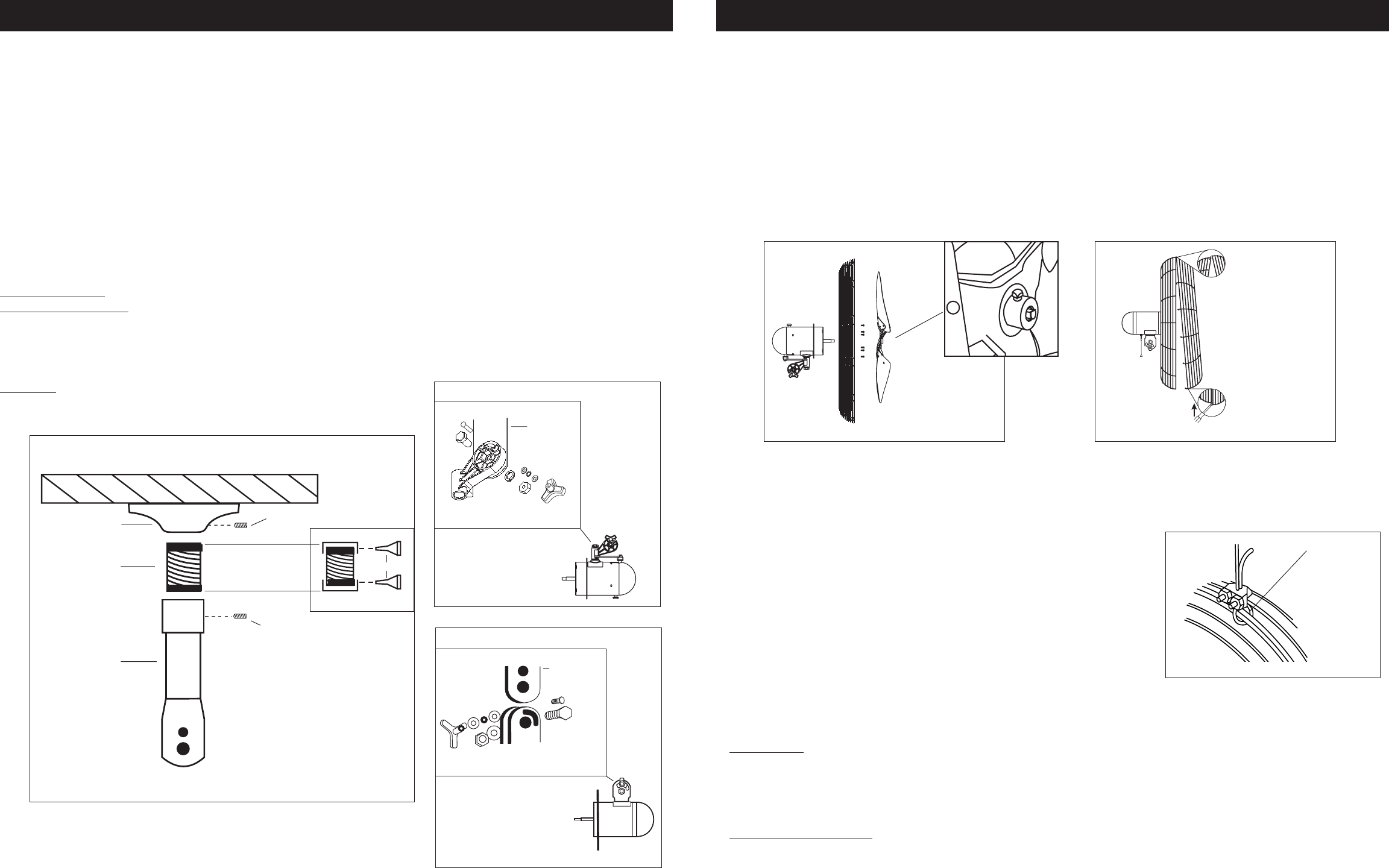

(Figures 1 and 2)

NOTE:

Distance mounted from the ceiling can be changed by using a length of 1-1/2” NPT pipe. Simply substitute your pipe for the provided

threaded pipe.

1. Locate the

Pipe Mounting Flange

, securely mount to ceiling structure. Ensure ceiling structure can safely support the installed Fan.

2. Open one tube of Loctite #243 by snapping tube neck just below end cap. Be Certain to follow all warnings noted on Loctite #243 tube.

3. Apply (1) ENTIRE tube of Loctite #243 onto the first 2 threads of one end of the

Threaded Pipe

that will be screwed into the

Motor

Mounting Adapter

.

(Figure 1 - Inset)

4. Screw

Threaded Pipe

into

Motor Mounting Adapter

. The

Threaded Pipe

MUST BE screwed in at least 4 full revolutions. Do not allow

Loctite #243 to dry before joining. Tighten provided

1/4” Set Screw

into

Motor Mounting Adapter

.

(Figure 1)

5. Open second tube of Loctite #243 by snapping tube neck just below end cap. Be Certain to follow all warnings noted on Loctite #243 tube.

6. Apply (1) ENTIRE tube of Loctite #243 onto the first 2 threads of the opposite end of the

Threaded Pipe

that is now screwed into the

Motor

Mounting Adapter

.

(Figure 1 - Inset)

7. Screw

Threaded Pipe with Motor Mounting Adapter

to the

Pipe Mounting Flange

.The

Threaded Pipe with Motor Mounting Adapter

MUST BE screwed in at least 4 full revolutions into the

Pipe Mounting Flange

. Do not allow Loctite #243 to dry before joining.

(Figure 1)

8. Tighten provided

1/4” Set Screw

into

Pipe Mounting Flange

.

(Figure 1)

CAUTION: FAN IS HEAVY AND MAY REQUIRE TWO PEOPLE TO MOUNT.

9. Attach pull string to motor speed switch, if desired

For Oscillating Motor: Place the flat section on the Motor Mounting Adapter next to the Motor Neck.

(Figure 2A)

For Non-Oscillating Motor: Slide the Motor Neck Slot over the Motor Mounting Adapter. Align the 1/2” diameter hole in the Adapter with the

1/2” diameter holes in the Motor neck Slot.

(Figure 2B)

10.Insert the 1/2” X 1” Hex Bolt (3/4” head) through the Motor Neck, and the Motor Mounting Adapter. Place 1/2” diameter Split Lockwasher

then the 1/2” diameter Hex Nut (3/4” head) and tighten fully with 2 adjustable wrenches.

11.From the same side of the Motor Neck, insert one 1/4-20 X 1 5/8” Carriage Bolt through the Arc-Shaped Slot in the Motor Neck and Hole

in the Motor Mounting Adapter.

To Fasten: Place one 1/4” Flatwasher, one 1/4” Internal Tooth Lockwasher, a second

1/4” Flatwasher and then tighten the Adjustable Knob over the remaining threads.

.

2New 8/04

5084416

3New 8/04

5084416

Figure 1

Pipe Mounting

Flange

Threaded Pipe

Motor Mounting

Adapter

Set Screw

GRILL AND BLADE ASSEMBLY

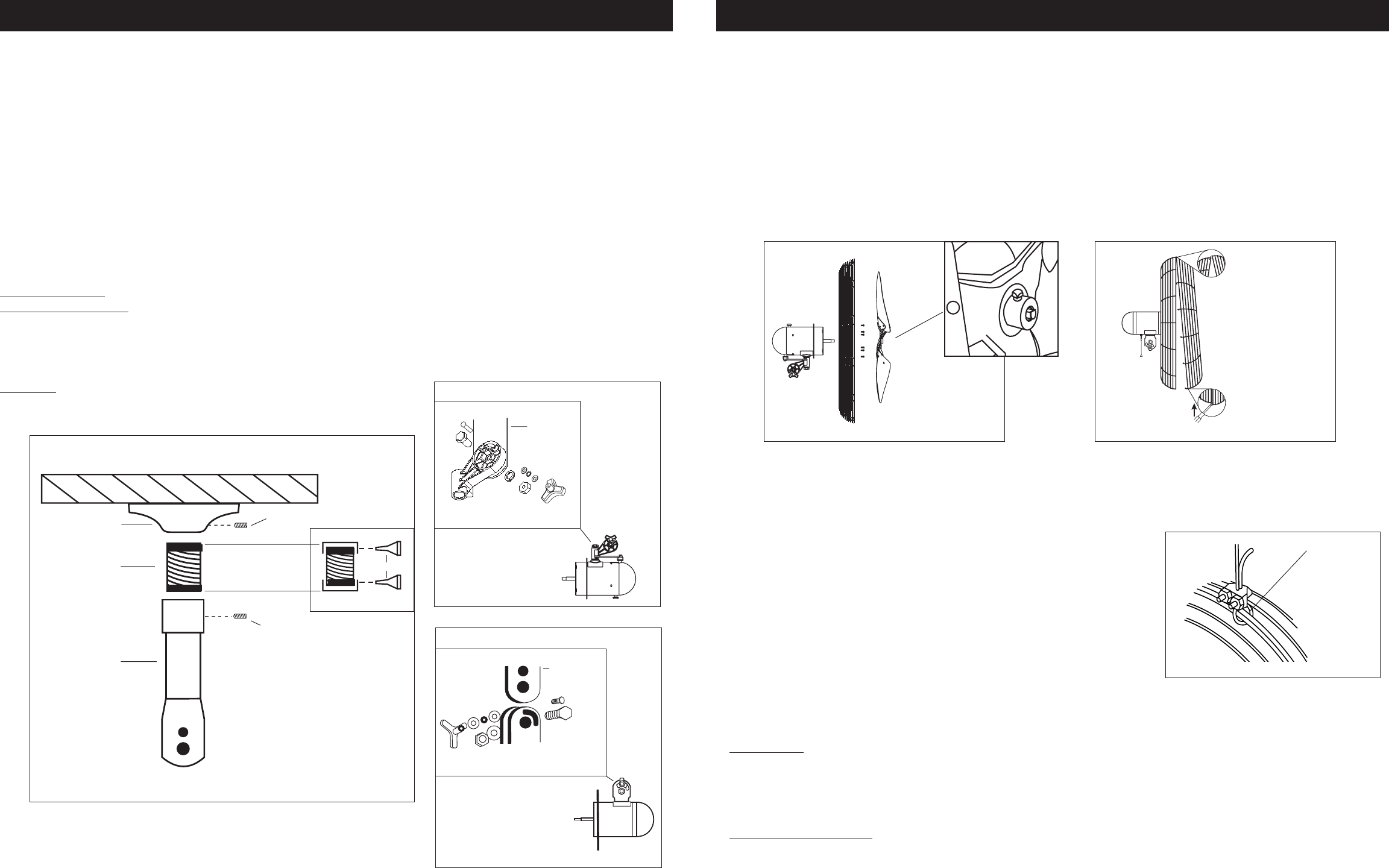

(Figures 3 and 4)

NOTE: The assembly of the blade and grill is identical, regardless if the Fan has an oscillating motor or a non-oscillating

motor. One of each is shown in the illustrations below.

1. Install the

Rear Grill

onto the

Motor

, lining up the six holes in the grill with the six threaded holes in the

Motor

. Install (6) 10-32 X 5/16”

Hex Screws through the

Rear Grill

into the

Motor

. Securely tighten all (6) screws.

(Figure 3)

2. Push the

Fan Blade

onto the

Motor Shaft

, centering the Hub facing away from the motor, until it stops against the shaft

(Inset A)

. Align

Square Head Bolt with flat of the

Motor Shaft

. TIGHTEN VERY SECURELY WITH AN ADJUSTABLE WRENCH. Failure to securely

tighten the Bolt could result in damage to the Fan and/or personal injury.

3. Hold the

Front Grill

so that the name, in the center, is right side up and straight across. Starting at the top: Fasten

Front Grill

to

Rear

Grill

by sliding the hooked wires on the

Front Grill

over the outermost ring on the

Rear Grill

.

(Figure 4 / Detail A)

. The bottom most hooks

will require the use of a flathead screwdriver to complete assembly. Stand behind the Fan. Slip the flat of the screwdriver between the

Front and Rear Grills, next to one of the unfastened hooks.

(Figure 4 / Detail B)

Pull screwdriver handle upwards towards the Rear Grill.

Slip the Front Grill hook over the Rear Grill outer ring with a push. Repeat procedure with remaining hooks.

CAUTION: DO NOT BEND WIRES ON THE FRONT OR THE REAR GRILLS.

Figure 3

Inset A

Oscillating Motor Shown

OPERATING INSTRUCTIONS

1. TO OPERATE: Plug cord into a grounded 120V, 60 Hz outlet. Select desired operating speed with pull cord on the rear of the motor:

First pull: High Second pull: Medium

Third pull: Low Fourth pull: OFF

NOTE: THIS FAN IS VERY HEAVY.

Failure to securely hold onto head assembly while adjusting head angle

could result in personal injury.

2. TO ADJUST HEAD ANGLE: While holding head firmly, loosen knob under motor (turn counterclockwise). Tilt head to desired position

FIRMLY retighten knob under motor.

NOTE: Motor Head Adjustment Knob and the On/Off Pull Cord have the same location on oscillating or non-oscialling models.

CAUTION: THE SECONDARY SUPPORT CABLE PROVIDED SHOULD BE

USED ANYTIME THE CIRCULATOR IS MOUNTED OVERHEAD FOR

ADDITIONAL SAFETY.

SECONDARY SUPPORT CABLE

(Figure 5)

1. Loop one end of Cable around the

Large Guard Wires

of both the Front and Rear Grills.

2. Attach a Cable Clamp with the "U" on the tail side of the loop leaving a tail approximately

1 to 2 inches. Tighten Clamp Nuts. Make sure no part of the Cable interferes with the Blade.

3. Wrap the other end of the Cable around a secure building joist, truss, or other support near the

Fan. Take up all excess slack in the Cable.

CAUTION: USE ONLY THE MOUNTING HARDWARE WHICH

IS RECOMMENDED FOR USE ON THIS FAN.

4. Attach the remaining Cable Clamp as indicated in Step 2. The excess tail should be trimmed

to extend 1 to 2 inches past the Clamp.

5. Check the Assembly to assure the Blade is free of all obstructions.

CAUTION: Use of the secondary support cable does not guarantee protection against

injury of persons, mounting of both the circulator and cable could fail if subjected to abuse, neglect or improper installation.

Detail B

Bottom Hooks

Detail A

Top Hooks

Non-Oscillating Motor Shown

Figure 4

Set Screw

Application Loctite 243

Loctite 243

Inset

Figure 2B

Motor

Mounting

Adapter

Exploded View for Detail

Non-Oscillating Motor View

Ceiling Mount Assembly

Large Guard

Wires

Figure 5

Figure 2A

Motor

Mounting

Adapter

Exploded View for Detail

Oscillating Motor View